The modern healthcare system features miraculous advancements in technology, treatments and methods of healing. The equipment used to diagnose and treat patients has changed radically in just the past 50 years. Doctors now have the means of looking at the human body in ways that could only be imagined on Star Trek before. Every day, medical science brings healthcare facilities closer to curing everything from cancer to the common cold.

Much of this advancement is a direct result of a greater understanding of pathogens, contamination and proper sterilization techniques, some of which have only been around for the last 20 years. It’s almost shocking to realize that much of our medical knowledge and understanding of healthcare procedures is predicated on things we’ve learned in just the past few decades.

The good news is that we now have better sterilization and reduced contamination in hospitals and healthcare facilities as a result. But in order to maintain these gains in quality care, medical facilities must remain vigilant in their practices to protect against accidentally transferring, contaminating, or spreading bacterium, viruses or other microorganisms within their facility. Without prompt attention to these issues, isolated cases can rapidly become major health issues.

How cleaners and disinfectants can create issues with medical equipment

Decontaminants and disinfectants are used as part of the sterilization process when protecting the safety of hospitals, clinics, care centres and offices. Protocols developed by the Centers for Disease Control and Prevention established standards for ensuring that contamination isn’t spread by people, equipment, instruments or materials used in medical facilities, standards which should be followed in every healthcare environment. These protocols help to keep patients safe and healthy during their visit, regardless of how long or short it may be.

However, disinfectants, cleaners and decontaminants are made of harsh chemicals, and some equipment and instruments don’t hold up well to even one cleaning, let alone a daily routine and possibly multiple exposures to these compounds. Because of the costs associated with replacing this equipment, some healthcare professionals may be tempted to minimize sterilization practices. Unfortunately, this increases the risk of cross contamination. The resulting rise in health issues can lead to increased hospital stays, increased medications, possible surgical intervention or even patient deaths.

It’s not surprising to learn that many pieces of equipment fall victim to the liquids that are meant to help hospitals maintain a safer environment. They can be corrosive to plastic and metal alike, shortening equipment life span and increasing costs for the facility. Given the cost to replace equipment that becomes compromised, finding a product resistant to the damages of disinfectants and cleaners would be a real game-changer to those hospitals and clinics.

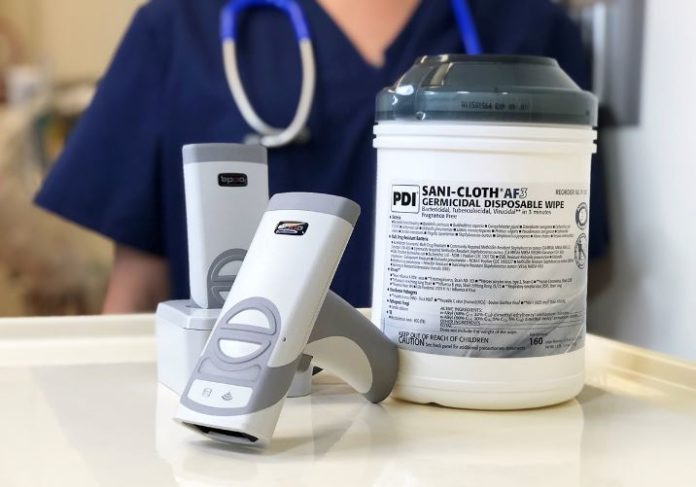

Code CR2700: Built specifically for healthcare facilities

The Code CR2700 is built specifically for the healthcare community and offers a number of features that are ideal for healthcare facilities. Among the advantages of the CR2700 are:

- Inductive charging, which means no exposed metal. This eliminates chemical corrosion caused by disinfectants and cleaners that can damage the charging pins.

- Bluetooth Low Energy 5 for enhanced data security, throughput and transmission range.

- Streamlined case eliminates hard-to-disinfect nooks and crannies.

PVC-Free CodeShield® medical-grade plastics stand up to harsh disinfectants. - Lightweight, ergonomic models in palm and handled configurations.

- Durable, quick-release rechargeable battery cartridges save time.

- Smart battery shows battery health with a visible fuel gauge.

- Visual, audible and haptic indicator customization for workflow needs.

- Patented dual-field optics, both high density and wide field in the same unit, add versatility and function.

- Patented glare reduction technology means reading barcodes on shiny surfaces is no longer a challenge.

- High-speed, omnidirectional reading of all barcodes used in healthcare makes the process faster and more accurate.

- Multiple programmable buttons allow you to create customized workflow processes.

- Pair to Bluetooth-supported Android, iOS and Windows devices and tablets.

- IP65 rating seals out dust and moisture for longer product life.

- CortexRM® Remote Management ready.

- Powerful data management capability with JavaScript.

- Code Complete service and extended warranty plans offer additional protection.

Being purpose-built for the healthcare environment, the CR2700 is an ideal fit for nurses, CNAs and healthcare professionals with varied workflows. Small enough to fit in scrub pockets, healthcare workers can carry the CR2700 from room to room for point-of-care activities like patient verification and medication administration. The CodeShield plastic housing can withstand multiple cleaning and disinfecting rounds in a day without degradation of the materials.

Try the CR2700 for yourself for free and see how versatile it is and how it holds up to your most stringent disinfecting regimen. Contact your CDW Account Manager to schedule your free demo.